Managing chemicals safely and securely has always been an issue and has become even more important in the last few years. The chemical industry has had a major focus on safety for decades, in the developed world it is very safe to work in the industry compared to other industry segments. The ICCA report card shows the reduction in injuries over the last decade. (see video below) There are, however, gaps in safety practices not only in the developing areas of the world, but also in the academic and government laboratories in more highly-developed economies.

There is a focus on safety and security management of chemicals world-wide. The chemical industry, through the International Council of Chemical Associations (ICCA) Responsible Care Process is working with the Strategic Approach to International Chemicals Management (SAICM) to improve safety practices. The ICCA companies are approaching this by focusing on introducing the Responsible Care process in developing economies and are currently concentrating on African countries.

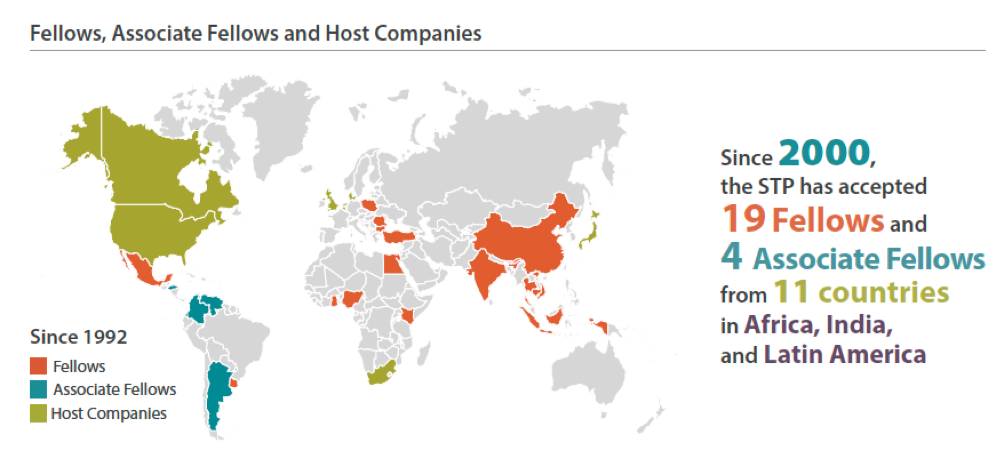

A long-term key goal of IUPAC has been to build chemistry-based capacity in developing countries. This involves actively pursuing a better understanding of chemistry and training people throughout academic institutions, industries, governments, and the public. IUPAC supports the ICCA via IUPAC’s Committee on Chemistry and Industry’s Safety Training Program and because IUPAC and ICCA have congruent goals to build safety and security capabilities.

Dr. Youssef is a professor of analytical chemistry who also works on numerous projects in his home country of Egypt to address problems related to chemical waste management, environmental protection, and air pollution monitoring. His goal was to increase his practical knowledge of environmental process safety management programs. As a result of the Safety Training Program Dr. Youssef hoped to address the factors that make the implementation of safety programs in the Middle East recycling industry more challenging. These include language, lack of good internet access, and lack of training programs. There is also a lack of hazard awareness.

Dr. Youssef is a professor of analytical chemistry who also works on numerous projects in his home country of Egypt to address problems related to chemical waste management, environmental protection, and air pollution monitoring. His goal was to increase his practical knowledge of environmental process safety management programs. As a result of the Safety Training Program Dr. Youssef hoped to address the factors that make the implementation of safety programs in the Middle East recycling industry more challenging. These include language, lack of good internet access, and lack of training programs. There is also a lack of hazard awareness.

Steve Nyamori is Deputy Director of the

Steve Nyamori is Deputy Director of the  Dr. Grover is the Chief Scientist at the

Dr. Grover is the Chief Scientist at the

Forty-Four people applied from many countries in Latin America. Five people were chosen and four were trained (the fifth person fell ill at the last minute). Attendees were from Argentina, Venezuela, Columbia, and Costa Rica. The course was 80 hours over two weeks and attendees rated the course very highly. Upon completing the training, they were designated STP Associate Fellows. They all committed to carry our safety related activity in their organizations when they returned home.

Forty-Four people applied from many countries in Latin America. Five people were chosen and four were trained (the fifth person fell ill at the last minute). Attendees were from Argentina, Venezuela, Columbia, and Costa Rica. The course was 80 hours over two weeks and attendees rated the course very highly. Upon completing the training, they were designated STP Associate Fellows. They all committed to carry our safety related activity in their organizations when they returned home. Ms. Toprak is Chief Chemical Engineer in the

Ms. Toprak is Chief Chemical Engineer in the